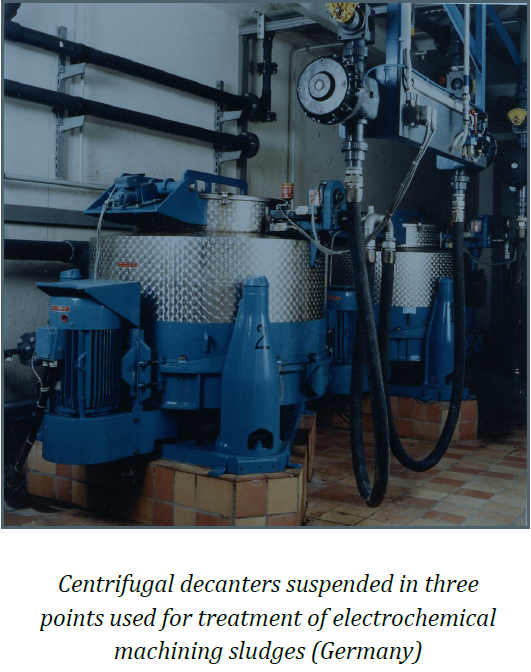

CENTRIFUGAL DECANTERS

For the metalworking, pharmaceutical, chemical, food and related industries

Centrifuges equipped with a solid decanting bowl, allowing separation of phases with different densities:

- Semi-continuous clarification of solutions containing small percentage of solids

- Continuous separation of two liquid phases

GENERAL FEATURES

- Pendular (DSC type) or visco damper suspension (DRA/DRC type)

- Construction materials : cast iron, mild and stainless steel

- Driven by axial motor (DRA) or lateral motor (DRC/DSC)

- Braking by electric drive system (DRA/DRC) or by disc braking (DSC)

- Solid or hooped bowl according to dimensions

- Partial or full opening lid according to application and removal principle of solid phase

- IP55 standard for motor and control panel

- Vapor tight construction for gas without pressure

- Independent local control panel

- Regulatory safety devices in accordance with applicable standards

CENTRIFUGAL DECANTERS type DRA/DRC

CENTRIFUGAL DECANTER type DSC

CENTRIFUGAL DECANTER WITH REMOVABLE EXTRACTION CAGE type DRC-K/DSC-K

Centrifugal decanter with removable cage for solids removal and liquid phase removal by overflow

Centrifugal decanter with removable cage for solids removal and liquid phase removal by overflow

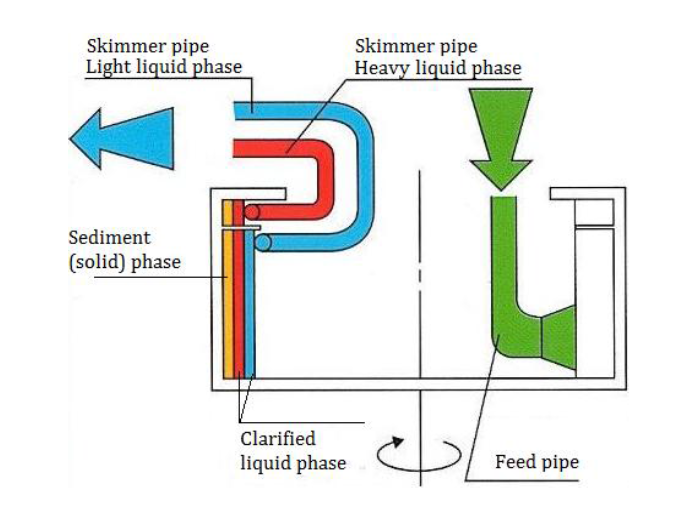

OPERATION

1- The bowl is set in rotation until optimal speed is reached

2- The feed material is introduced into the bowl on a continuous basis through the feed pipe

3- The heavier phase (solid or liquid) is drawn towards the bowl sidewall under the action of the centrifugal force

4- The lighter clarified liquid phase is removed from the bowl on a continuous basis :

Either by overflow over the top of the bowl

Either with a skimmer pipe. The fixed position of the skimmer is near the bowl rim’s inner diameter, in order to optimize the bowl’s useful volume for the heavier phase, consisting of the heavier liquid and/or solids.

5- When the bowl is full of sediment, the feeding is stopped (manually by an operator, or by cycle timer, ot external control signal).

6- Removal of the sediment :

Either while the bowl is rotating, using the skimmer pipe, applicable when the sediment is a sludge

Either when the bowl is stopped, manually or using a removable cage when the sediment is too compact/dry

PRINCIPLE :

Separation of solid phase and two liquid phases having different densities.

Construction materials : stainless steel, chrome-nickel steels, high chrome nickel alloy, titanium

Special coatings : halar, ebonite

Decanting bowl designs:

- Solid bowl

- Cylindrial or conical

- To ensure that the liquid phase maintains the same rotational speed as that of the bowl, baffles can be fitted inside the bowl. This prevents unbalance and helps to separate the phases of two liquids with similar densities. The baffles can be supplied fixed or as removable items to allow easier cleaning.

- Fast bowl removal for small units

- Drain plugs in bowl base

Removable cage, with or without textile bag for solids removal

Discharge device: manual or motorized skimmer pipe,supplementary skimmer pipe available

Solid/liquid selector valve available

Explosion-proof motor and electrical equipment according to European or US standards

Vapor tight centrifuge for gas under pressure, ready to receive a nitrogen blanketing system

Nitrogen inertizing

Speed variation using a frequency modulated drive system

Double casing for cooling or heating

Sterilization of centrifuge possible on small diameters

Mounting on base plate or mobile skid for small units

Bottom discharge centrifugal decanter: special design only suitable on large bowl diameters, and for specific applications

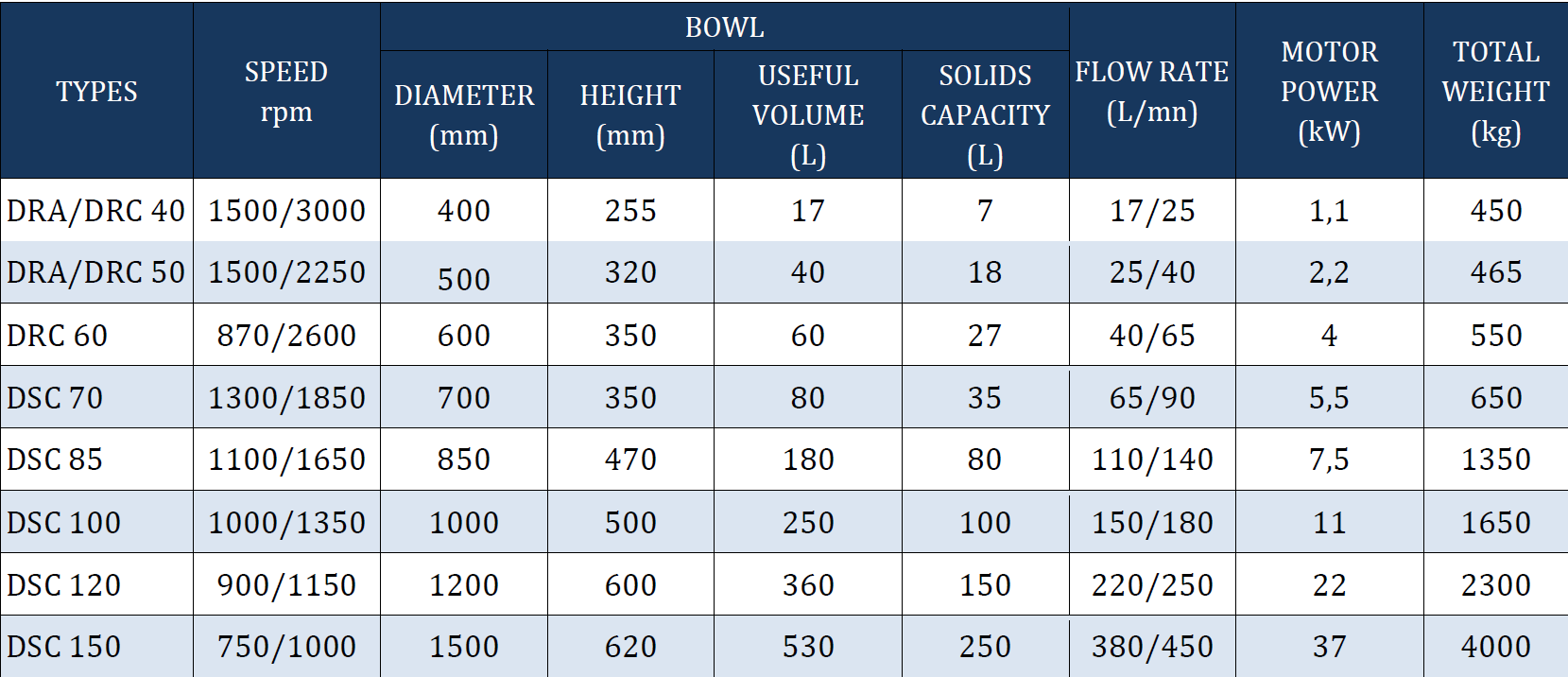

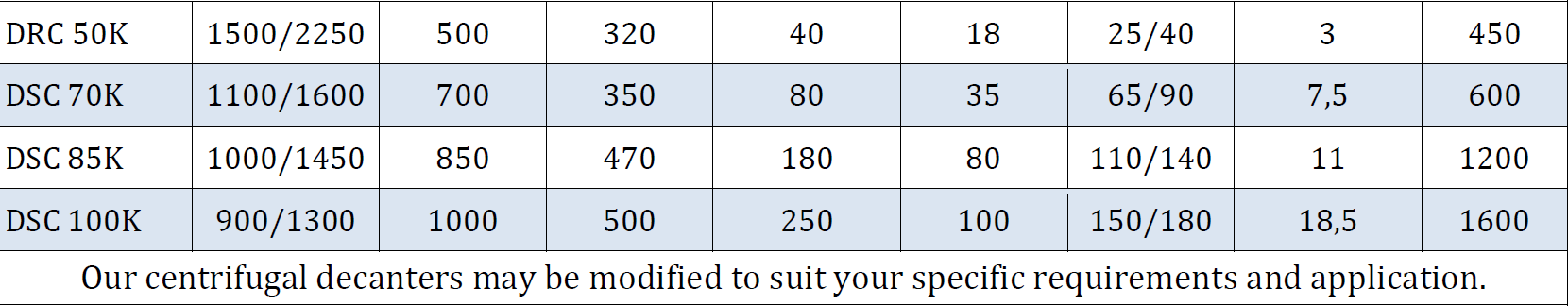

TECHNICAL DATA

DECANTER WITH REMOVABLE EXTRACTION CAGE

Thanks to our extensive experience in design and manufacture of high technology centrifuge systems developed over 150 years, ROUSSELET ROBATEL is your preferred partner for any standard or special need that centrifugation can address.